In this project, VitalFluid, supported by the Greenhouse Horticulture business unit of Wageningen University & Research (WUR) and VDL, is developing a PAW reactor for in-situ production of nitrate in feed water in greenhouse horticulture, in combination with the disinfection of feed water.

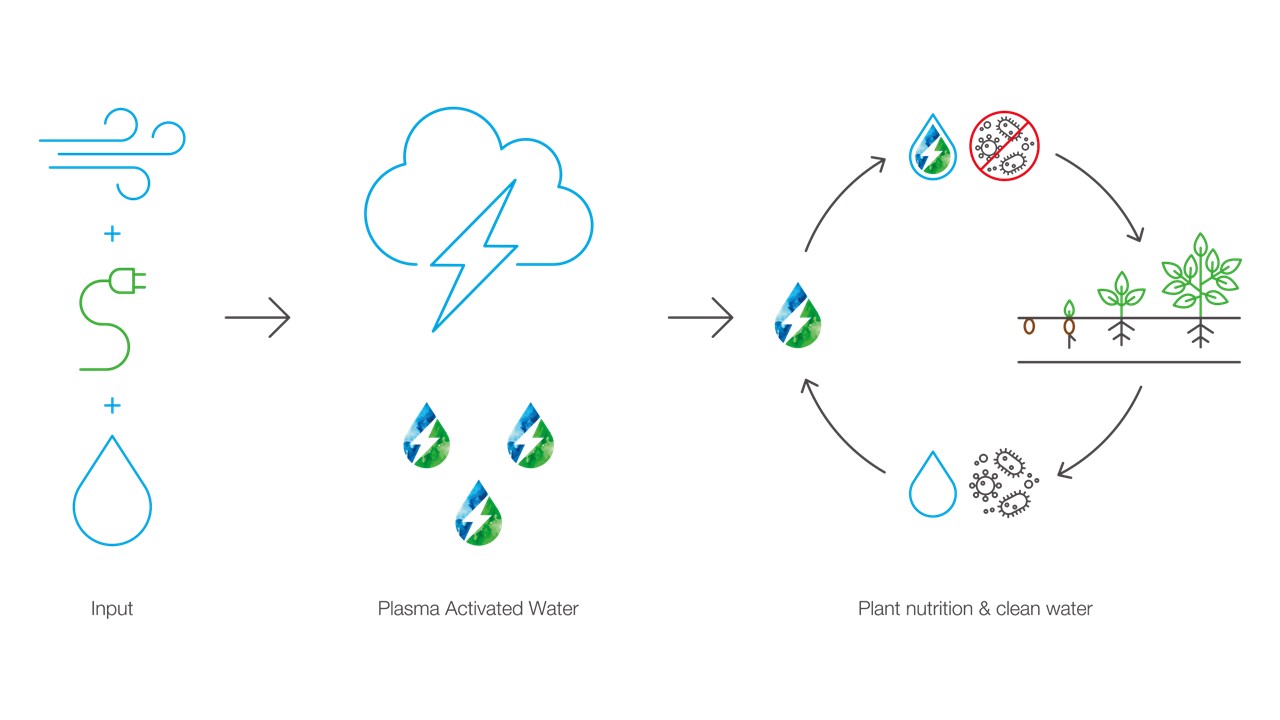

The unit which will be developed uses only ambient air, water and (green) electricity. In the unit the plasma process will result in plasma activated water. This plasma activated water has two main properties; first the water is disinfecting, and second it will remain in water with a content of nitrate, an important nutrient for crops.

This allows growers of crops under glass to produce an alternative to the synthetic nitrogen fertilizer that is currently still produced from fossil fuels (natural gas).

PAW contributes to the carbon neutral economy and to the agricultural transition. Today’s nitrates are produced from natural gas; PAW from water, air and electricity. In fact, if renewable electricity is used, PAW is completely carbon neutral.

The PAW process also disinfects the irrigation water, making the purchase of other systems to purify the irrigation water (UV/Ozone/H2O2) unnecessary.

The project largely consists of 4 work packages:

VitalFluid aims to bring PAW systems to the market by the end of 2023 that can produce PAW with variable, but consistent intensities for fertilization and disinfection of nutrient water in greenhouse horticulture. In addition to the social benefits, this offers growers commercial benefits. Based on signals from the market, it is expected that this will provide a healthy business case for VitalFluid.

This project was made possible in part by the European Fund for Regional Development under REACT-EU.