Our company VitalFluid B.V. was established in 2014 and is located in the Brainport area on the High Tech Campus in Eindhoven. Over the years we have increased our knowledge and expertise focusing on the treatment of water with plasma. Our broad experience in the field of plasma technology allows us to present our company as a knowledge centre of plasma activated water. Thereby we focus on hygienic and fertilizing applications in agriculture, like seed treatment, plant protection and nitrogen fixation with plasma technology. Following the environmental and social pressure in society for a sustainable agriculture we are aiming to offer circular food production with clean alternatives for agrochemicals.

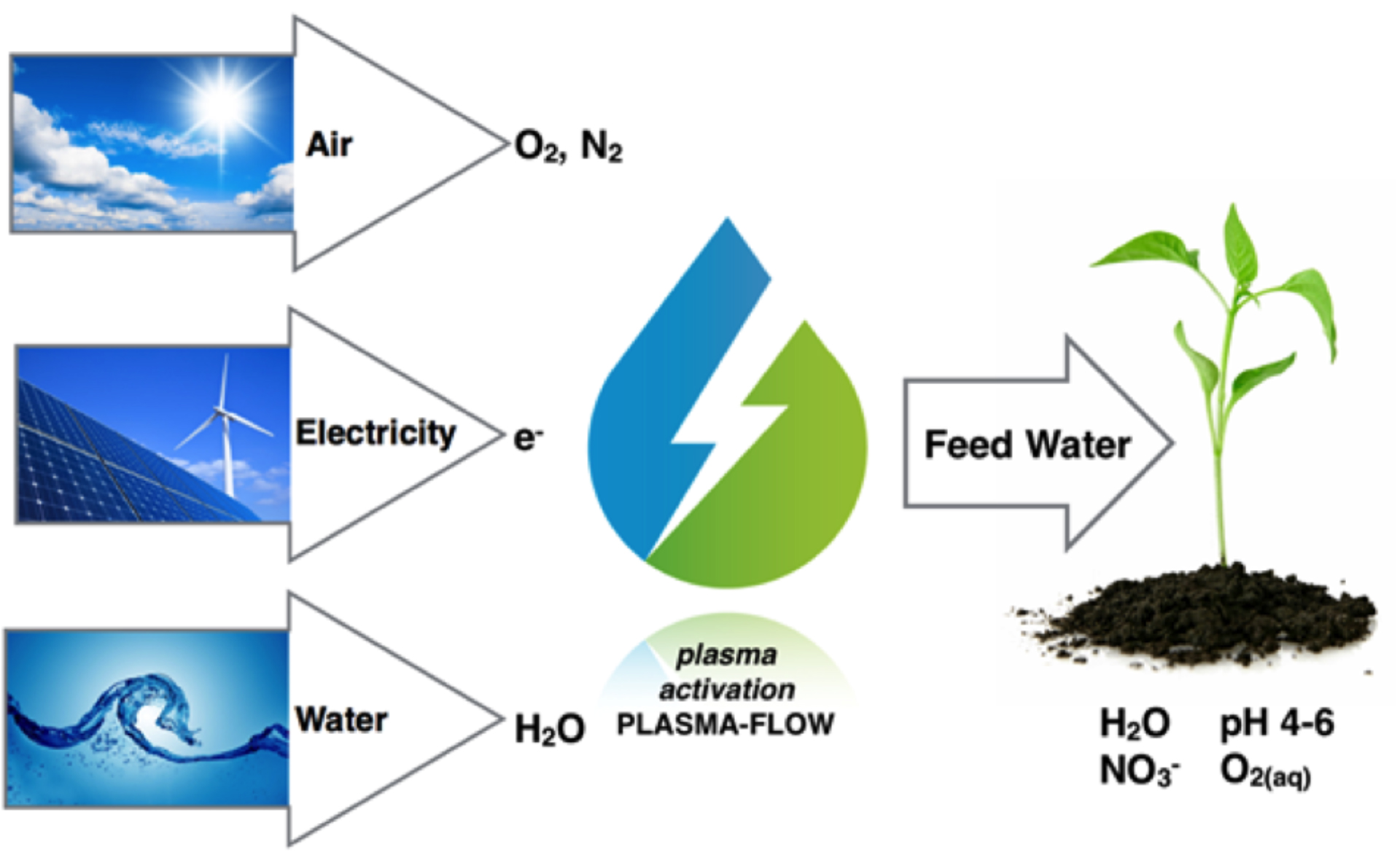

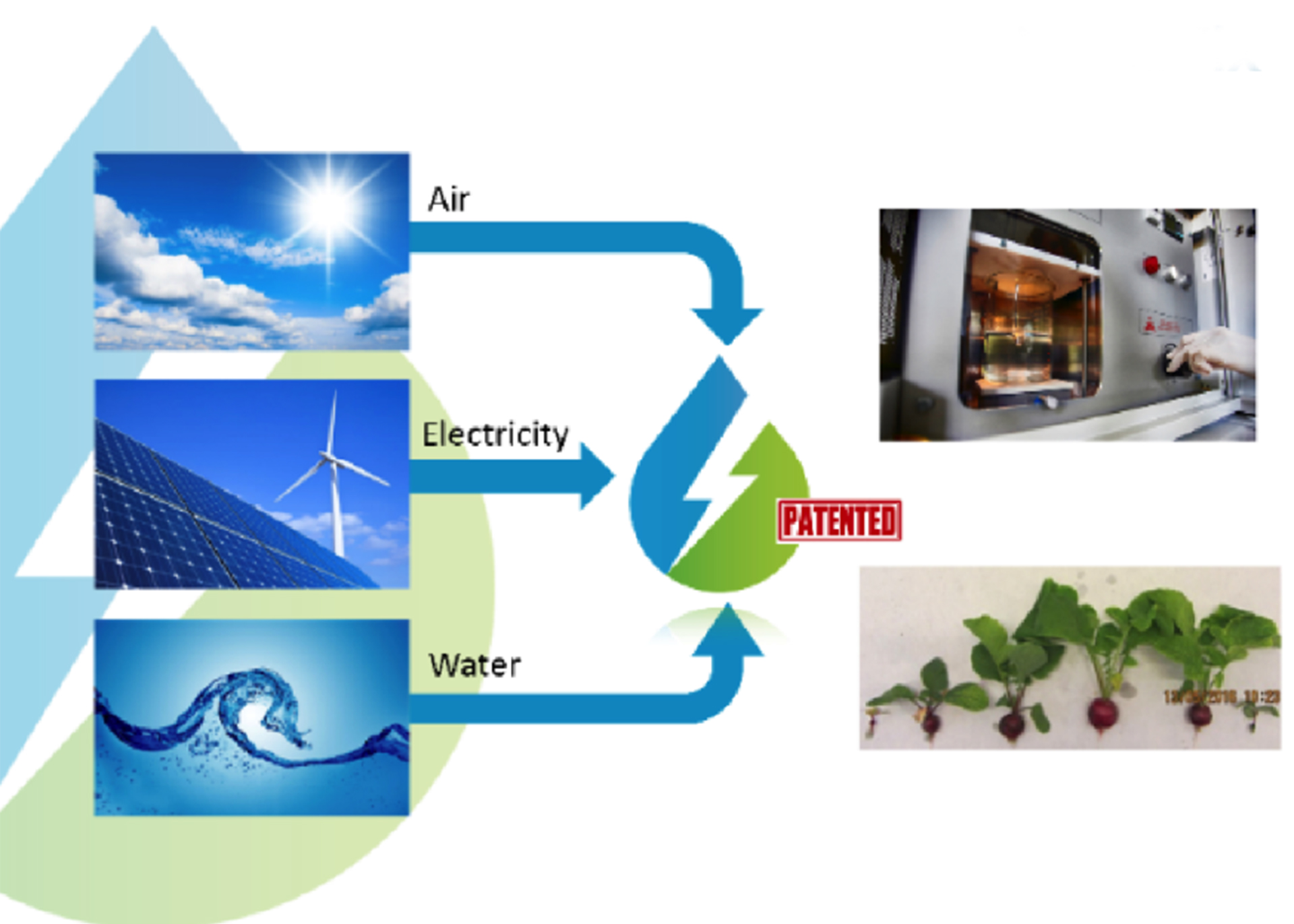

Plan2Fix (PLAsma N2 (nitrogen) FIXation) is European Union’s Horizon 2020 research and innovation funded project and offers a new solution for horticultural companies to produce the most important fertilizer in crop production: nitrogen. Our equipment can be used on site at the point of use, making only use of water air and electricity. The produced nitrate can be applied to the crops by drip irrigation.

The process of using plasma for nitrogen fixation is copied out of nature. Lightning is one of nature’s ways to fixate nitrogen. Our process is a biomimicry of lightning in a thunderstorm.

Thanks to the Horizon Financing programme, we are able to realize two large scale Plan2Fix systems that will be used in demonstrations in vertical farming and in a horticulture greenhouse in cooperation with end-users and stakeholders. Plan2Fix systems can be used by horticulture companies and drip irrigation farming that use liquid nitrogen fertilizers.

Our Plan2Fix units extract Nitrogen directly from the air and dissolves it into water on the spot. Our patented plasma technology ionizes air by applying a high voltage so that its nitrogen and oxygen ions dissolve in ‘plasma activated water’ (PAW) to create nitrate (NO3) that is readily absorbed by plants.

Plan2Fix produces a liquid N-fertiliser that can be customised to deliver the exact amount of N to the crops in drip irrigation systems.

The end users of our Plan2Fix systems are horticulture companies that make use of liquid fertilizers to fertilize their crops. Our systems can be used by all farmers that make use of fertigation techniques or drip irrigation systems in agriculture. Our technology is specifically interesting for farmers that generate their own electrical energy.

Parties interested in Plan2Fix and those who want to receive more information about the field demonstrations can contact us via info@vitalfluid.com.

Plan2Fix systems offer the following advantages for horticulture companies:

A cost-effective means of extracting nitrogen directly out of air, break it down with plasma and dissolve into water in the form of nitrate. Additional benefits is that the process disinfects and enriches the water with extra oxygen.

The process runs on electricity and no transport is needed since the fertilizer is produced in situ at the point of use.

The process can be powered with renewables, that can lower the costs of nitrogen fertilizer even further.

Our systems are modular and fit any size of company, the farmer is in complete control of the production of its own nitrogen fertilizer.

We will demonstrate Plan2Fix in the horticulture test facility in Bleiswijk of the Wageningen University and Research in Bleiswijk (www.wur.nl) and a vertical farm BrightBox in Venlo (www.brightbox-venlo.nl). The demonstrations of Plan2Fix systems were executed from the spring until December 2021 .

Production of Plan2Fix takes places at the Brainport area Eindhoven, a specialized high-tech manufacturing center in Europe.

Parties interested in Plan2Fix and those who want to receive more information about the field demonstrations can contact us via info@vitalfluid.com.

Demonstration of Plan2Fix systems were executed from the spring until December 2021 at the following locations:

To stay informed about the Plan2Fix project and the field demonstrations, please contact info@vitalfluid.com.

Below the results of the demonstrations of Plan2Fix systems are shown. Please contact VitalFluid for the full reports.

The Plan2Fix project is divided in several work packages, each with its own goal.

To optimise plasma properties and enhance nitrogen uptake we measure and monitor internal and external process parameters with sensors to ensure reproducibility. Design of large-scale electrode configurations to be integrated in the nitrogen scrubber. The electrodes will be tested on effectivity, safety and life-time. Control algorithms will be determined and implemented, as well as an easy to use user-interface.

Realisation and production of all parts, systems and subsystems needed to build 4 Plan2Fix systems on skid or containers for an easy transportation. The Plan2Fix will be a modular system where the output volume can be adjusted by stacking multiple modules together.

Validate and demonstrate Plan2Fix in practice in CEA advanced greenhouses with the typical crops: tomato, cucumber, lettuce and strawberry. Ensure easy to operate and smooth connectivity. Test the use efficiency of the energy generated by Plan2Fix in the plasma-activation process to heat the greenhouses.

Ensure that the complete realisation and production of Plan2Fix can be carried out after Phase 2 SME Instrument project.

Protect the IP of the results of the project. Prepare the expansion strategy and develop our international commercial network outside NL. Realise training on installation for distributors and workshops with potential clients. Prepare and carry out dissemination/promotion/communication activities to gain exposure & awareness. Educate our potential clients about the main benefits of Plan2Fix.

| Milestone number | Milestone title | WP number |

|---|---|---|

| MS1 | Upscaled Plan2Fix Reactor | WP1 |

| MS2 | Realization of prototypes for on-field demonstrations | WP2 |

| MS3 | On-field demonstrations of Plan2Fix | WP3 |

| MS4 | Industrialization & marketing actions | WP4 WP5 |

This project has received funding from the European Union’s Horizon 2020 research and innovation programme under Grant Agreement number 873862.